- ARB Equipment

Move Further, Faster

Efficient and reliable solutions for automating complex processes

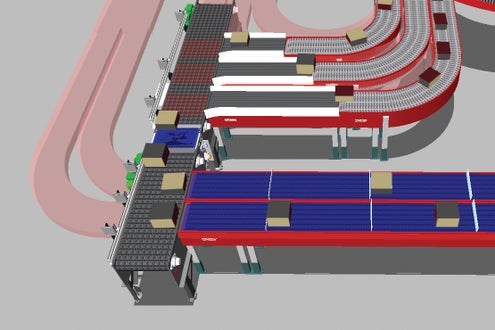

Activated Roller Conveyors

Automate processes and areas in ways once thought impossible.

Activated Roller Belt™ (ARB™) technology is a patented, automated conveyance solution that creates new possibilities for system or line layouts. Proven in thousands of installations worldwide, ARB equipment enables efficient, gentle, and reliable product handling for applications and areas that more traditional technology cannot support.

Our team can help you realize the full value of ARB technology. Depending on your layout and circumstances, the right ARB solution can help you achieve major operational improvements, including:

- Increased throughput

- Reduced equipment footprint

- Lower total cost of ownership or system acquisition costs

- Enhanced safety with reduced guarding requirements

- Flexibility to handle challenging or changing product types, both now and in the future

When Intralox says it will do something, it does. Their equipment performs as they say it will.

Jay Moris

Invata Intralogistics Founder

Find Your SolutionWhich ARB Solution Meets Your Needs?

Select your industry or product type to see the equipment options most relevant to you.

To refine your choices, filter by product application.

Service SpotlightLayout Optimization

Intralox helps identify and solve your biggest challenges by optimizing your line layout, reducing project risk, and utilizing solutions that bring the most value to you.