Marie Experiences “Enlightenment” with Intralox AIM Switch

The AIM technology has a simple design, but the improvements it delivers for cleanability and worker experience are dramatic. It has brought enlightenment to our process!

Frédéric Jacquet

Marie–Viriat Project Engineer

Customer Objectives

Since 1983, Europe’s largest poultry-producer LDC Group has offered a variety of food products for sale throughout France under the brand Marie. Its plant in Viriat produces a wide range of items, including two kinds of pre-cooked lasagna (vegetarian and bolognese). The lasagna is prepared in small plastic trays along a single processing line before being split into two lines and fed into a linear oven. The plant dedicates two shifts a week to this process.

Previously, Marie used a slat switch chain to divert lasagna trays between oven lines. This equipment was the source of several challenges. Sanitizing the slat switch was very difficult: detergent could not be used, and the switch’s protective cover made it nearly impossible to access all required areas. Even with especially long periods dedicated to cleaning, the plant could not achieve its desired hygiene levels. Other problems with the equipment included the large amount of lubrication it required, as well as high costs for spare parts.

Intralox Execution

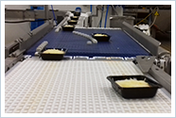

Marie wanted a new switching solution that would eliminate these problems. The plant found just such a solution with Intralox’s AIM Switch. Intralox Active Integrated Motion (AIM) technology enables automation in washdown environments, offering a tray pack handling solution never available before. The AIM Switch provides gentle, yet fast and reliable tray switching, eliminating maintenance, downtime, and safety problems associated with competing technologies. Installed in 2016, the Viriat plant’s AIM Switch was completely washable, required no protective covering, and occupied a smaller footprint than the previous solution.

Results

The AIM Switch has brought Marie dramatic sanitation gains. The Intralox solution provides better access for cleaning and is compatible with detergent use, so desired hygienic levels are achieved with 60% less cleaning time. Labor and water use have been reduced as well. Intralox supplemented the installation with guidance on cleaning and sanitation best practices.

The switch, which requires no lubrication, has also helped the plant reduce maintenance and spare-parts expenses. Marie has maintained throughput levels while benefiting from gentler product handling (no product spillage issues). The Intralox solution generates less noise than its predecessor, contributing to a more comfortable experience for workers. And the AIM Switch’s compact design, combined with the lack of equipment covering, means personnel can now communicate and walk throughout the area with ease.

Compared to the slat switch, Marie projects that the AIM Switch will reduce related maintenance and labor costs by 92%. Based on this projection, if this line ran under typical operating conditions (five days per week, two shifts per day), payback would be only six months. Project engineer Frédéric Jacquet is impressed: “Once again, an Intralox innovation resolves persistent issues. The AIM technology has a simple design, but the improvements it delivers for cleanability and worker experience are dramatic. It has brought enlightenment to our process!”