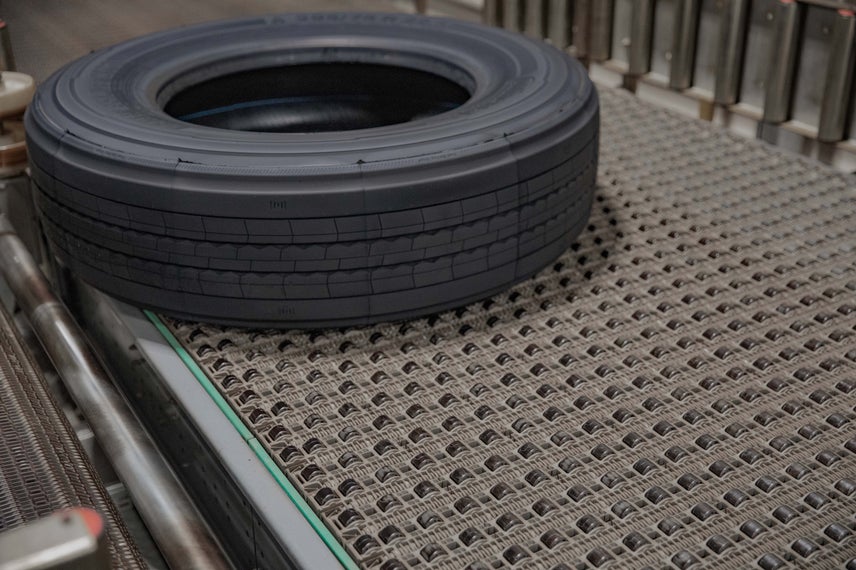

Tire conveyance solutions, from mixing to final finish and beyond

Intralox creates significant economic value for tire manufacturers worldwide by providing total conveyance solutions for the entire plant.

We provide innovative, proven solutions and layout optimization for all the areas of your tire production facility, as well as comprehensive services, support, and guarantees that ensure total success. Whatever your need–whether it’s a single retrofit, an area upgrade, or a plant-wide project–Intralox’s belt, equipment, and service offerings deliver optimal results for your plant.

Tire plant applications

Where can Intralox make the difference for you?

Mixing and MillroomProven solutions for mixing and millroom

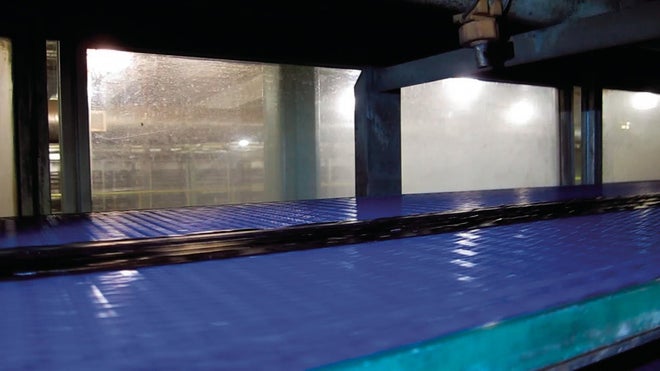

Intralox mixing solutions minimize belt repairs, slippage, mistracking, edge damage, product sticking, and potential rubber contamination. Thousands of mixing and millroom installations have reduced downtime and maintenance costs for global tire manufacturers around the world by thousands of dollars per year.

Proven applications include mixer infeed (weigh and charge conveyors), mixer takeaway conveyors, mill-to-mill conveyors, dip tank conveyors, festoon pull-out conveyors, and wig-wag/stacker conveyors.

Our proven solutions for mixing and millroom help you:

- Minimize belt repair and replacement

- Eliminate slippage and mistracking

- Decrease sticking and rubber jams

- Avoid edge damage

- Minimize the potential for rubber contamination

Download our Mixing Area Solutions interactive brochure (PDF)

Producing Results

* Based on retrofitting a wire mesh belt to Intralox dip tank solution

Insights and Results

Tire manufacturers find success with Intralox solutions