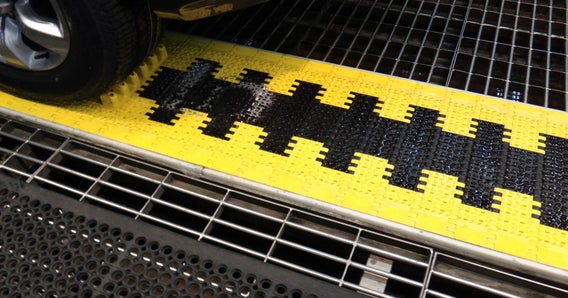

Conveyor belts and systems for the automotive industry

Intralox’s long-lasting, easy-to-install belt and equipment solutions for automotive plants deliver measurable increases in productivity, quality, and worker morale.

Our innovative products, combined with our global support structure, reduce the risk of expensive downtime in automotive assembly while improving worker ergonomics. We work with major automotive and equipment manufacturers across the world, developing patented technologies and customized solutions for the automotive industry’s most pressing conveyance challenges.

Automotive manufacturing applications

What can Intralox's belts and equipment help you achieve?

Electric Vehicle BatteryInventing the future of EV battery conveyor technology

Intralox’s future-ready, innovative solutions scale electric vehicle (EV) battery production and increase speed to market in your plants. By partnering with us on your next EV project, you can enable future-ready flexibility and touchless, gentle handling of cells, modules, and packs.

- Eliminate elevators, returnways, and pallets

- Reduce conveyor needs and footprint by up to 50%

- Achieve full-width support and configurability with ARB technology

- Handle products as small as 4 in x 4 in (102 mm x 102 mm) and up to full-size battery packs

By the Numbers

Inventing the Future of EV Battery Conveyance

Intralox’s future-ready, innovative solutions scale battery production and increase speed to market in your electric vehicle (EV) plants.

Insights and Results

Automotive manufacturers find success with Intralox solutions