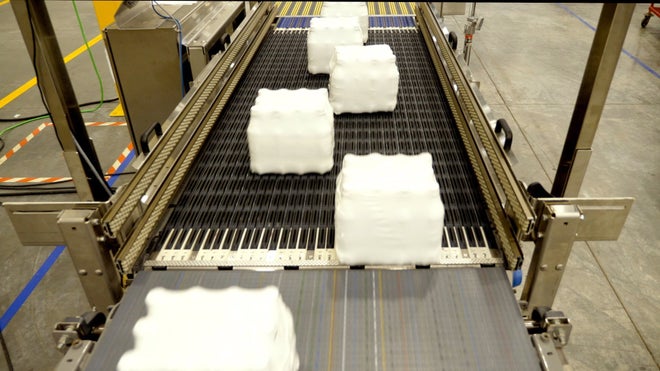

Conveyor belts and equipment for bottled and canned beverages

Intralox’s beverage specialists combine deep industry knowledge with innovative technologies and a comprehensive approach to line layout optimization. No matter what you produce—whether it’s beer, wine, soft drinks, water, or anything else that’s bottled or canned—we can ensure you get the most out of your critical conveyance equipment.

With Intralox’s solutions for the beverage industry, you can:

- Increase operational and energy efficiency by combining multiple pieces of equipment into one

- Reduce upfront investments and total cost of ownership (TCO)

- Eliminate dead plates on case conveyors and mass conveyors

- Save floor space on new lines or equipment

- Build future-ready, flexible lines

Solutions for beverage plants

What can Intralox's belts and equipment help you achieve?

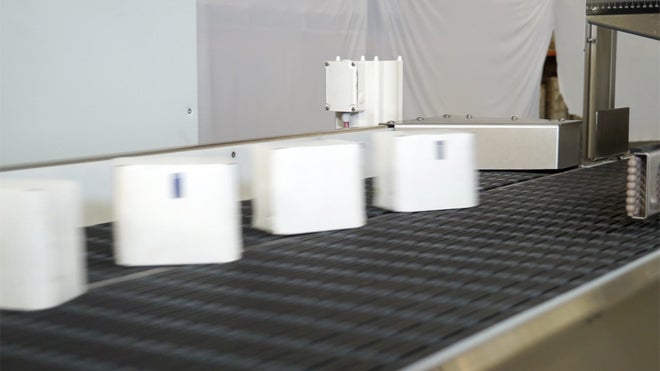

Combining EquipmentCombine multiple pieces of equipment into one with ARB technology

Your layout may require discrete functions like rejects, case turns, and 90-degree transfers. But that doesn’t mean you need a separate conveyor for each.

With ARB technology and Intralox’s Packer to Palletizer program, you can combine multiple pieces of equipment on your beverage line into a single machine. Especially for complex areas with multiple infeeds and outfeeds, ARB solutions—including S7000, S7050, and DARB equipment—can enable more functionality with less equipment in less space.

Intralox’s Packer to Palletizer specialists for the beverage industry can help you:

- Improve efficiency by adding room for accumulation

- Fit equipment into small spaces previously not thought possible

- Reduce your capex costs and TCO for a project

- Simplify maintenance by reducing motors and pieces of equipment

Producing Results

Industry InsightsFewer Transfers, Fewer Problems

Bring your operation back to life with dead plate–free tight transfers

Insights and Results

Beverage makers find success with Intralox solutions